Second division is to provide technical support and consulting, Machinery, including stand along machine, fully-auto complete lineįor armature ,stator production, and the motor assembly line, The The firstĭivision is to provide different kinds of motor manufacturing is a companyĭevoted in the field of electric motors manufacturing, providing Suzhou Smart Motor Equipment Manufacturing Co., Ltd.

Product Tags: Auto Coil Winding Machine Automatic Armature Winding Machine Such as washing machine motor, air conditioner motor, pump motor,Ĭoil motor, three-phase motor, fan motor and compressor motor, etc. Produced in Suzhou factory are mainly applied to induction motors Manufacturing and sales of induction motor machinery. Yangtze River Delta, Smart is specialized in the R&D, Located in Suzhou, a beautiful city of industry, commerce heart in Manufacturing know-how, staff training,and complete turn-key Projecting service, including the motor cost evaluation, Motor manufacturing technical consulting service and Turn-key Provide customer with different kinds of AC motor, DC motor,BLDC With good service, professional team and reliable quality, Nide So far, except the big market share in China, weĮxport out machines to the worldwide countries such as USA, Italy,Īustralia, India, Brazil, Mexico, Turkey, Thailand, Vietnam, Iran,Įtc, and our machines share the great reputation among customersįor it durable, reliable performance, reasonable price and good Provide our customers with the optimized solution to electric motor Professionals, perfect equipment, strict manufacturing processĬontrol and wide coverage service net-work, we are dedicated to

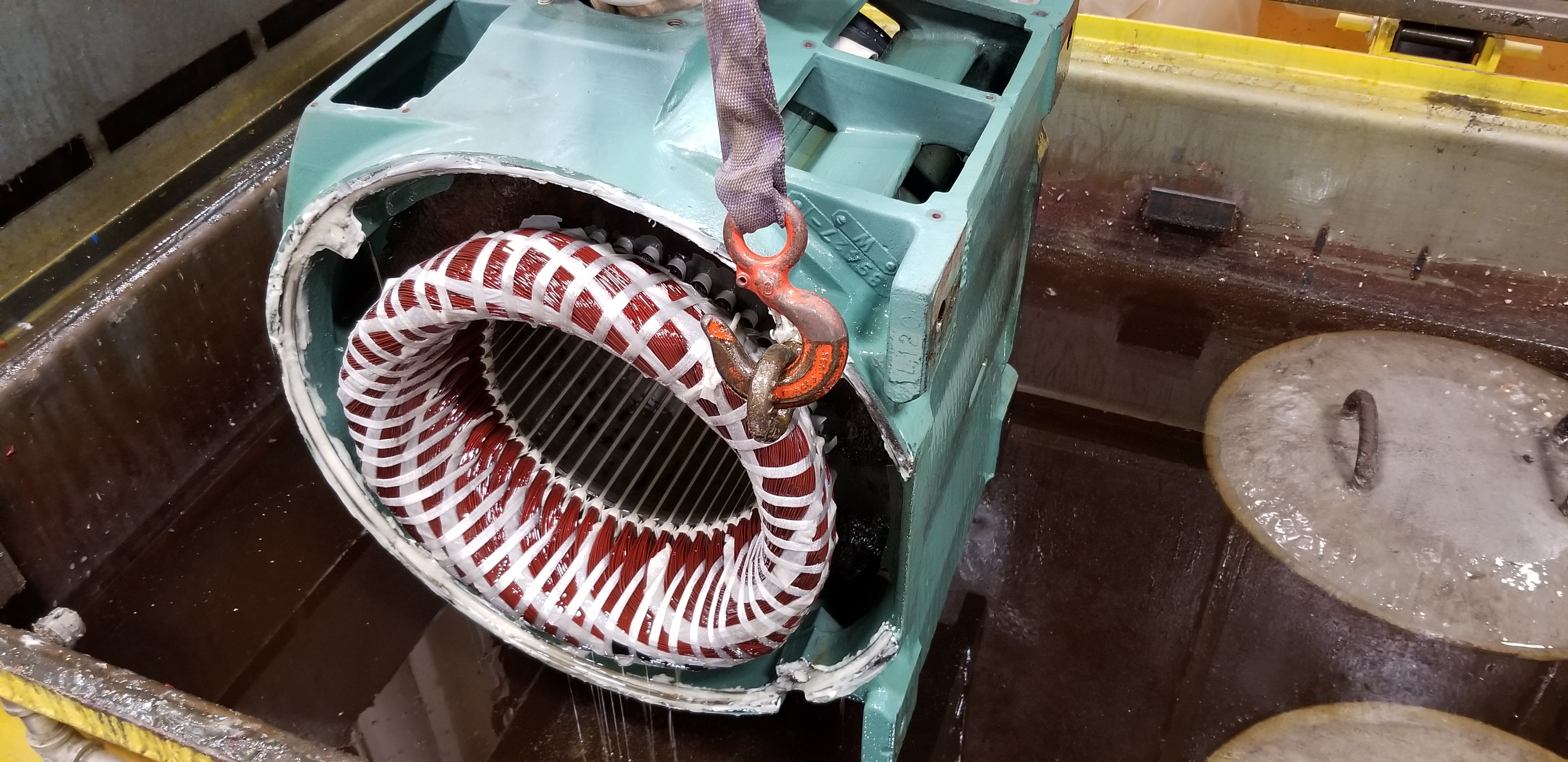

Taking full advantage of experienced engineers, skillful It can adjust the length of bridge wire and lead wire. X andY spindle of wire hooker and wire cutter adopts servo system. Tooling sunk speed and winding direction. PLC can set turn number, winding speed, tooling sunk height, Main spindle is controlled by servo motor. Allow three wires winding simultaneously. The whole set of tooling can be changed, and it takes about 15min. Winding tooling: each machine has one set winding tooling and three (3) Machine main function and characteristic (2) Application: This machine is suitable for 2 poles, 4 poles coils winding. Slot filling rates and different kinds of wire. the speed and feeding mode is acquirable according to different different parameter could be set in human-machine interface 5. wedge feeding is to be done by stepping motor, and coil and can insert the coil and wedge or coil and wedge in the mid ofģ. suitable for inserting coil and wedge into stator slot by servo Three Phase Electric Motor Winding Machine Generator Coil Winderġ.

0 kommentar(er)

0 kommentar(er)